benecel™ hypromellose

chemistry: cellulosics

SDS Link >

additional content coming soon

additional content coming soon

additional content coming soon

additional content coming soon

Benecel™ products are high purity, water-souble, nonionic cellulose ethers. Benecel™ hypromellose (hydroxypropyl-methylcellulose or HPMC) is a versatile excipient with a variety of applications. HPMC is the most widely used polymer in hydrophilic matrix systems with widespread use in controlled-release dosage forms. The Benecel™ family of pharmaceutical products, including Benecel™ XR and XRF HPMC, custom grades of Benecel™ HPMC, and Benecel™ DC HPMC, provides a full portfolio to support the controlled release of a broad range of APIs and manufacturing processes.

Benecel™ XR and XRF HPMC grades:

Benecel™ XR and XRF are high-viscosity grades of HPMC with optimized polymer structure and particle morphology for use in matrix controlled-release systems.

Features and Benefits:

- Optimized polymer structure and particle morphology

- Consistent particle size distribution and bulk density

- Enhanced compactibility at high tableting speeds vs standard grades

- Fine particle size grades available (XRF)

Custom Grades of HPMC for Controlled Release:

Achieving a desired drug-release profile has traditionally involved blends of different molecular weights of particular polymers. Blending, however, can increase release-profile variability. Custom grades of Benecel™ HPMC were developed to obviate the need for blending and offer a potential solution to the problem of dissolution variability.

Features and Benefits:

- Increase predictability and reproducibility of drug release profiles

- Decrease research and development time needed to optimize blend ratio

- Decrease manufacturing time- no need to blend and manage multiple raw materials

- Opportunity to develop custom excipients

Directly Compressible HPMC Grades:

Directly compressible (DC) grades enable the production of controlled-release formulations with the convenience of the most widely used tablet-binding mechanism. These Benecel™ DC HPMC grades offer good powder flow, content uniformity, and compressibility, making them well suited for direct compression.

Features and Benefits:

- Improves product flow characteristics

- Reduces processing times

- Identical, stable dissolution profiles compared with “CR” grades

- Improves content uniformity

- Reduces production costs

- Retains tensile strength after double compaction (roller compaction) process

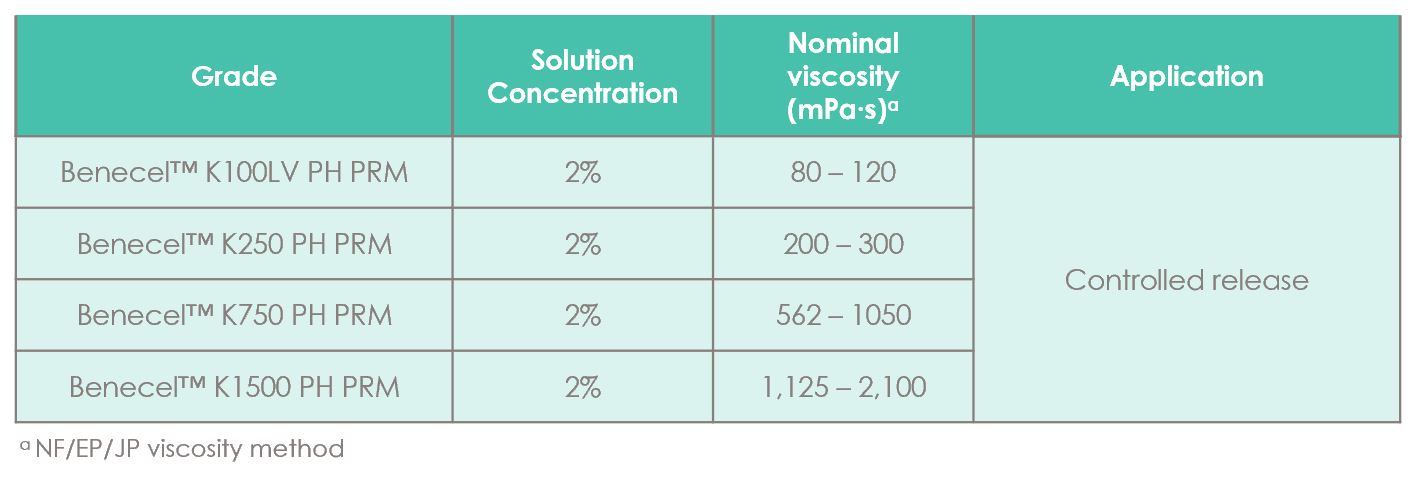

benecel™ methylcellulose and hypromellose product grades:

Click on the links below for more information

related links

related literature

related technical literature

- Invulnerability to Alcohol Induced Dose Dumping

- Hydrodynamic Robustness in Modified Release Matrix Systems

- Benecel™ HPMC for Nutraceutical Modified Release Dosage Forms

- Hydrodynamic Robustness of HPMC and HPC Based Modified Release Marix Systems

- Substitution Type on Molecular Weight and Drug Solubility on Release Kinetics

- Modified Relase Drug Dosage Forms: Performance Similarity to Competitive Grades

- Dissolution Performance and Robustness of New Hypromellose Controlled-release Polymers

- Impact of Molecular Weight and Molecular Weight Distribution of Hypromellose in Reducing Drug Release Variability from Erosion Dependent Matrix Systems