performance specialties

who moves molecules like chess pieces? we do.

Ashland knows that a single ingredient can have a big impact and, for us, every day is an opportunity to find a new solution to a new challenge. We have teams of solvers ready to solve your next challenge. With the combination of our specialty ingredients, technical expertise, research and development capabilities our solvers are working to provide solutions to a broad range of applications - from pencils and paper to mining and manufacturing there's nothing too big or small for the team at Ashland. First we listen, and then look to science for solutions. Then we develop test and try and we'll do that over and over again until we find a solution that works for you.

read more >

-

adhesives additives

who has solutions that really stick? we do

read more >Ashland's synthetics, cellulosic and guar-based polymers are typically employed as binders, rheology modifiers and tack enhancers in latex-based and water-soluble adhesives.

In these systems, Ashland's natrosol™ hydroxyethyl cellulose and aquaflow™ water soluble polymers deliver superior performance in thickening, improving sag resistance, increased cohesion and adhesion, as well as in achieving the required viscosity.

Aqualon™ & blanose™ carboxymethyl cellulose are an excellent choice for non-staining wallpaper adhesives, delivering a thick, smooth, and clear paste with superior adhesion properties.

Polyvinylpyrrolidone, pvp/va™ and gantrez™ products are commonly used as binders in glue sticks, providing safe and superior adhesive performance.

Polyvinylpyrrolidone, PVP/VA, klucel™ hydroxypropyl cellulose and aqualon™ ethylcellulose are also used in solvent borne, hot melt, pressure sensitive, re-moistenable and re-pulpable adhesives.

In addition, dextrol™/strodex™, easy-wet™ and surfadone™ surfactants are excellent wetting agents. Drewplus™ foam control agents are great defoamers in water-based adhesive formulations.

V-Pyrol™ (N-vinyl-2-pyrrolidone) and V-Cap™ (N-vinyl-caprolactam) are versatile reactive diluents for free radical radiation-curable adhesives, with use on a wide variety of substrates. Both monomers provide unique benefits as reactive diluents, such as increased curing speed, improved adhesion, enhanced hardness and tensile strength.

products

Adhesives addtives products are listed below, use the filters to find the products that meet your specific needs.

-

advanced and traditional ceramics

who gets fired up at the thought of solving a problem? we do.

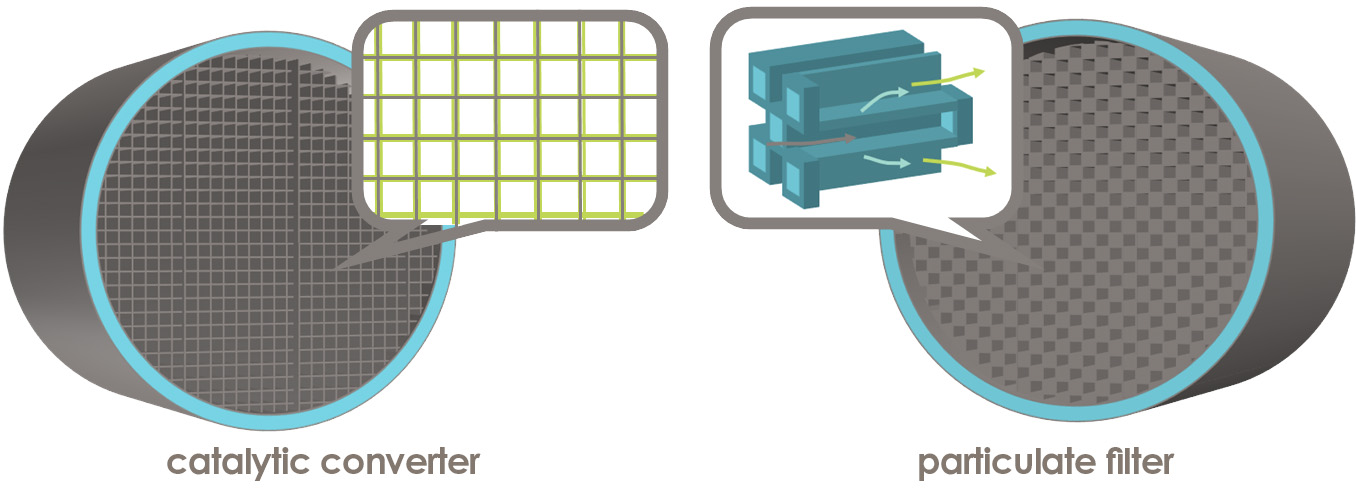

read more >From glazes that don't drip to stronger greenware to the advanced ceramics used in catalytic converters, and environmental filters, Ashland's knowledge in traditional and advanced ceramics can help you reduce waste and increase profits. Ashland products strengthen greenware making it less prone to breakage both before and during the firing process. And, our rheology products help create glazes that don't run or drip keeping your ceramic designs beautiful.

advanced ceramics

Manufacturers of advanced ceramics such as catalytic converters, gasoline & diesel particulate filters and industrial environmental filters require ingredients that provide the right amount of plasticity and workability during the shaping and molding process, while maintaining firmness of the wet mass after extrusion and before/during drying (wet green strength). Other advanced ceramics like catalyst carriers made into different shapes and using various shaping techniques (extrusion, dry pressing, isostatic pressing, etc.) also require organic binders to provide strength and cohesion of the shaped ceramic product.

During the drying process, these ingredients help ensure uniform, controlled drying and prevent the formation of cracks and blisters that can affect the performance of the converter, filter and other shapes. Although the needs are the same, different binders are used for the different manufacturing processes depending on raw materials, equipment as well as end product requirements. All manufacturers want to minimize costly equipment maintenance and repairs so they are also looking for products that help reduce wear and tear on manufacturing equipment and completely burn so there is little to no residue to deal with after manufacturing. Ashland offers a variety of products that can help solve these manufacturing needs.

traditional ceramics

To create beautiful ceramics, artists are looking for binder ingredients that increase the plasticity or workability of the material while providing enough strength to maintain the shape during the drying stage. Ashland products are also used as rheology modifiers to allow the glaze to go on easily without dripping or running. These products also produce a strong, tight bond between the glaze and the ceramic body to prevent both damage to the surface prior to firing, and cracking during or after firing, which are especially important for both food and beverage applications.

products

Ashland offers a large variety of chemically different cellulose ethers, which differ in chemistry allowing them to be used in different media / solvent systems depending on the shaping or application process. Some products develop their full potential when dissolved in organic solvents, other dissolve in water and polar solvents and others are purely water soluble.

-

Electronics

who gets turned on by the opportunity to solve? we do.

read more >The explosion of digital and electronic communications and technology has increased the need for products that are cleaner, better and easier to use. Ashland chemists get charged up with the prospect of innovations that aid the manufacturing process of ceramic capcitors, plasma display panels and solar cells. We continue to apply science to find breakthrough solutions for your electronic products.

Ashland solvers track trends to provide solutions for the ever-changing world of electronics. Needs change as technology advances and Ashland can help you keep on top of these changes. For instance, Ashland's ethylcellulose polymers provide very clean burn-out performance in thick metal and specialty electronic pastes. These organic, solvent-soluble derivatives of cellulose act as binding agents and can be used in the manufacture of multi-layer ceramic capacitors, plasma display panels and solar cells. Our relentless pursuit of solutions and improvements has yielded high quality products that can be used in numerous solvent systems to comply with the quality control systems in the manufacturing process of various electronic products.

industrial laminates:

Arofene® phenolic resins are used for electrical grade laminating such as printed circuit boards.

- excellent Non-Conductive Properties

- solvent-Based Systems

- meet Electrical Specifications: XX, XXX and XXXCP

products

Electronics products are listed below, use the filters to find the products that meet your specific needs.

-

batteries and energy storage

finding solutions for a longer life

read more >Ashland goes the extra mile when it comes to finding solutions and now we can help you do the same with longer-life batteries. The rate of change in the world can leave some ideas in the rear-view mirror, but Ashland anticipates changing needs to stay one step ahead. It's not a 'plug 'n play' when you work with Ashland. The Ashland solvers look at all the positives and negatives of possible solutions and technologies to find the one that best fits your need. Recharge your products and markets through collaboration with Ashland.

lithium-ion battery innovation

Generating renewable energy from the sun and wind is a growing trend. How to effectively store this energy on a large scale is a growing challenge. The increased market for electric and hybrid vehicles creates an ever-growing need for longer-life batteries to expand the driving range. Ashland thrives on putting science and chemistry to work to provide solutions to these and other challenges. As a leading supplier of a wide range of specialty additives and ingredients Ashland provides binders to the lithium ion battery (LiB) industry. soteras™ MSi, a unique binder for high-capacity silicon-based anodes found in lithium ion batteries, is among the most recent innovations from Ashland. Able to be processed using standard industry practices, its ability to control swelling results in superior cycle performance yielding longer battery life.

featured products:

- soteras™ CCS-V binder for ceramic coated lithium ion battery separators

Soteras™ CCS-V binder enables separator producers to meet ever more stringent safety requirements from lithium ion battery cell producers. It employs Ashland’s unique 2-component cross-linking system:

1. unique polymer which promotes adhesion to separator

2. cross-linking agent to ensure thermal and mechanical stability - bondwell™ aqueous polymers

Bondwell aqueous binder ensures effective anode slurry preparation and graphite binding

products

Products for battery applications are listed below, use the filters to find the products that meet your specific needs. - soteras™ CCS-V binder for ceramic coated lithium ion battery separators

-

Textiles

who is dyeing to work with you? we are.

read more >Whether a fad or trend fashion plays a role in most people's lives. Hemlines go up and down as lapels and ties get narrow or wide and the same holds true with pant legs. Regardless of the style, color and prints change like the seasons. Ashland ingredients for textile printing help prints stay brighter, bolder and crisper. Better dyeing techniques results in improved fade resistance keeping your customers looking great - longer. Let Ashland weave together some of our best products, technology, testing, service and solutions for your textile prints.

products

Textiles products are listed below, use the filters to find the products that meet your specific needs.

-

Welding

who forges unbreakable bonds with customers? we do.

read more >Used in a variety of industries, welding yields exceptionally strong bonds between materials. The thermoplastic metals and alloys, that are used to make welds are coated with flux, which assists in the formation of the welded bond. Ashland products improvde the the bonding and coating uniformity of the flux to the welding rod. Strong bonds depend on a highly consistent, smooth coating that helps prevent imperfections. Ashland's quality doesn't fluctuate.

products

Welding products are listed below, use the filters to find the products that meet your specific needs.

-

emissions control & catalysts

who helps create cleaner emissions? we do.

read more >emission control ceramics

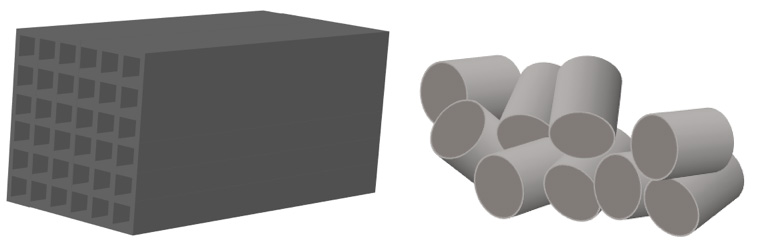

Manufacturers of advanced ceramics such as catalytic converters, gasoline & diesel particulate filters and industrial environmental filters require ingredients that provide the right amount of plasticity and workability during the shaping and molding process, while maintaining firmness of the wet mass after extrusion and before/during drying (wet green strength). Other advanced ceramics like catalyst carriers made into different shapes and using various shaping techniques (extrusion, dry pressing, isostatic pressing, etc.) also require organic binders to provide strength and cohesion of the shaped ceramic product.

During the drying process, these ingredients help ensure uniform, controlled drying and prevent the formation of cracks and blisters that can affect the performance of the converter, filter and other shapes. Although the needs are the same, different binders are used for the different manufacturing processes depending on raw materials, equipment as well as end product requirements. All manufacturers want to minimize costly equipment maintenance and repairs so they are also looking for products that help reduce wear and tear on manufacturing equipment and completely burn so there is little to no residue to deal with after manufacturing. Ashland offers a variety of products that can help solve these manufacturing needs.

catalytic washcoats

The most important part of an emission control product is the catalyst, mainly platinum group metals (PGM’s). Those catalysts are typically applied onto an inorganic support in form of a slurry. Those thin coatings, the catalytic washcoats, needs to have controlled rheological properties depending on the way of application. Pseudoplastic or Newtonian flow properties are the most common ones. Ashland products help adjusting the rheology to become suitable for the application and secure stability even under harsh (often strongly acidic) conditions.

activated carbon extrusion

Similar to ceramic substrates or particulate filters also activated carbon can be extruded with help Ashland binders. Typical shapes are honeycombs, pellets or sheets. Outstanding plasticity is one of the key properties provided by Ashland. Activated carbon containing canisters are used in the automotive segment to adsorb evaporating fuel gases and feed them back into the combustion engine. Those systems help saving thousands of tons of fuel globally per day and prevent the fuel gases from being released into the environment.

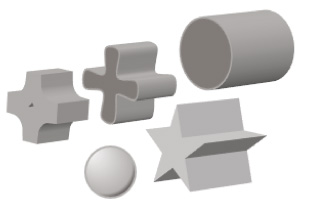

catalyst supports & bed topping media

Other advanced ceramics like catalyst carriers made into different shapes and using various shaping techniques (extrusion, dry pressing, isostatic pressing, etc.) also require organic binders to provide strength and cohesion of the shaped ceramic product. Industrial catalysts, often shaped by extrusion only require small amounts of additives to secure the required plasticity, extrudability and also have an impact on porosity depending on chemistry chosen.

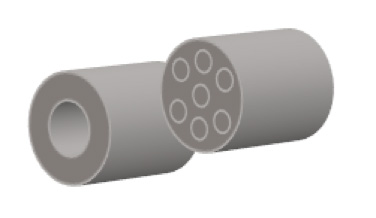

ceramic filter membranes

Purification of liquids through nano-, micro- or ultra-filtration is requiring ceramics with a well defined porosity. Those ceramics, in tubular or sheet form are also often manufactured using extrusion processes. Good plastification for an optimal extrusion is key and so is shape retention. Ashlands product portfolio offers various products as extrusion binders, which need to be chosen well for an optimal result.

products

Emissions control and catalysts products are listed below, use the filters to find the products that meet your specific needs.

-

intermediates

Who loses sleep over the last 1%? We do.

read more >Ashland’s intermediates business unit is known as one of the world’s leading producers and suppliers of 1-4 butanediol (BDO), Tetrahydrofuran (THF), n-methyl-pyrrolidone (NMP) and gamma-butyrolactone (GBL, BLO) in addition to other downstream products. Our products are used in applications as diverse as shoe soles, pharmaceuticals, water filtration, electronics and more. As we go to market around the world we make a promise to our customers about what it will be like to work with us and what we can accomplish together. We are always solving - helping our customers find solutions to the complex challenges facing them in their own marketplace.

Our people take pride in understanding our customers’ needs, market dynamics and the complex challenges that exist when competing in a global market environment. Our passionate, knowledgeable team works tenaciously to identify opportunities and trends in this fast-changing market to quickly respond and optimize the value we provide to our customers throughout all regions of the world.

All of our products are produced in fully accredited world scale plants. We are diversified in how we produce BDO and hold a patent for the Geminox process utilized at our Lima, OH facility. In addition to great products and technology, Ashland is regarded as one of the most reliable global producers of BDO and its derivatives. Our integrity and reputation is built on a solid foundation of providing great service, high quality products and customer-centered solutions. It’s something we are proud to earn every day.

products

Intermediates products are listed below, use the filters to find the products that meet your specific needs.

-

membranes

who breaks down barriers and filters out the competition? we do.

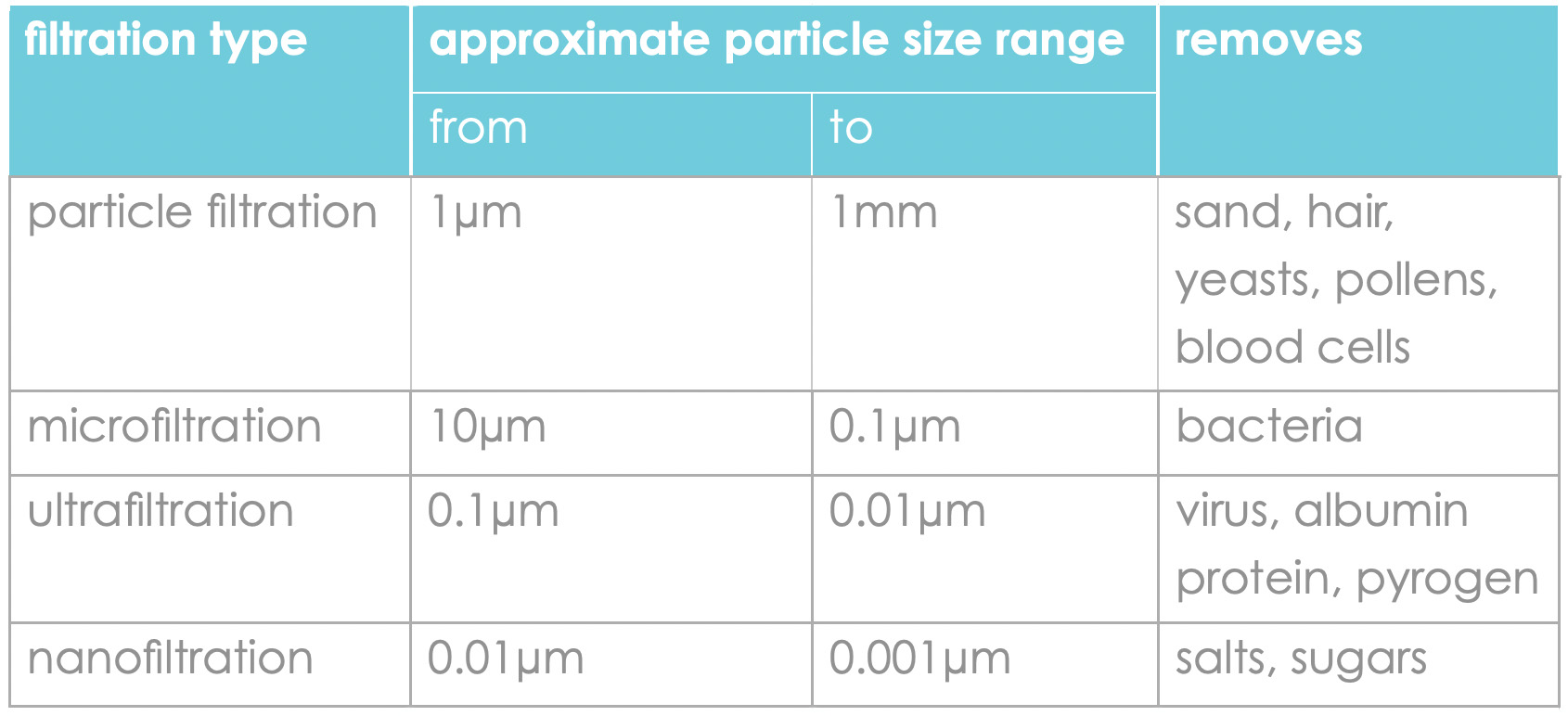

read more >Filtration is the removal of contaminants from liquids or gases by passage through a microporous medium such as a membrane. The level of filtration (or size range) required depends on the size of the impurities that are removed.

There are 4 main categories:

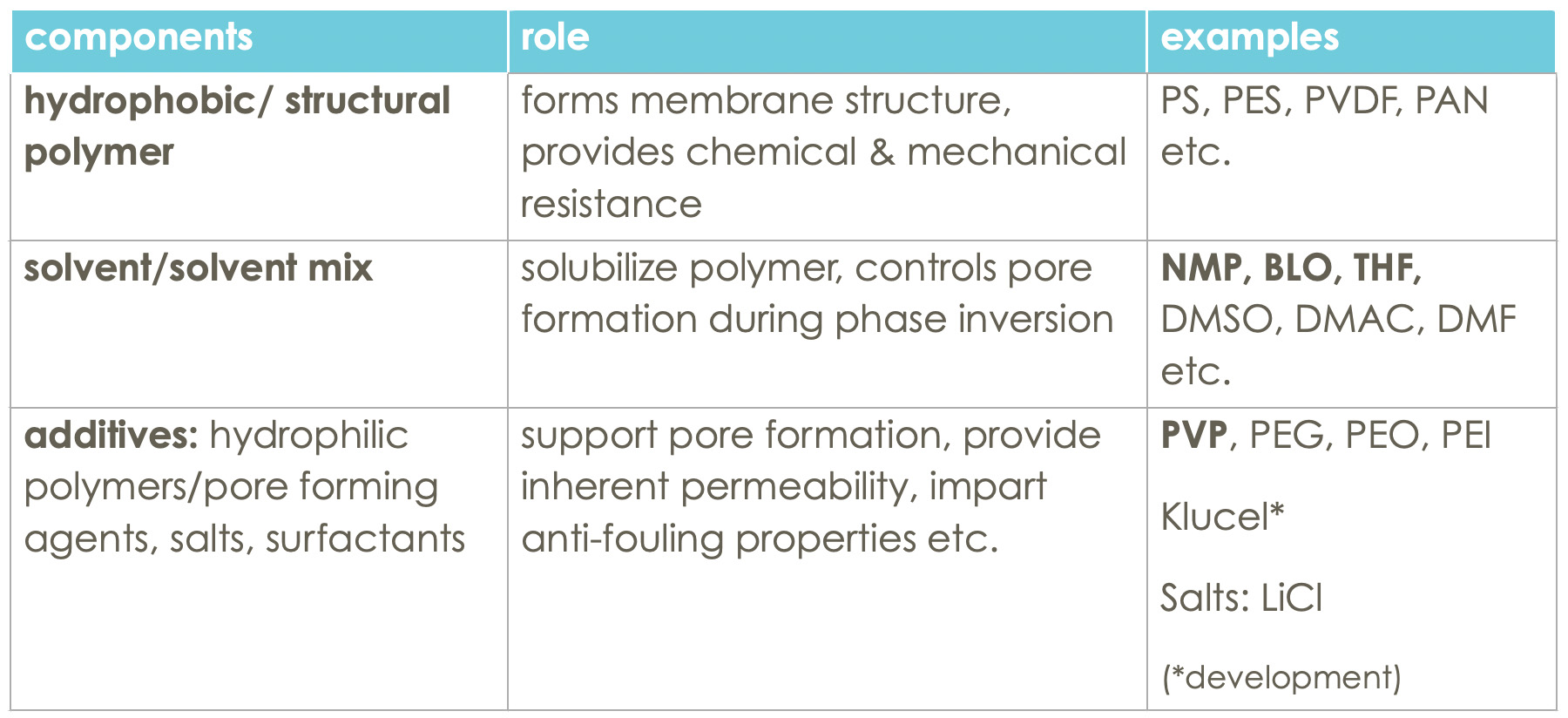

General composition of membrane doping solution contains below components

In the manufacturing process of filtration membranes, many additives can be used. These additives are often the essential components for the functionality of the end products.

Additives such as hydrophilic polymers, pore formers and salts are common types. Ashland acetylenic products such as polyvinylpyrrolidone (PVP) and its copolymers (such as PVP/VA™) are often added to hydrophobic polymers (such as PES, PS, PVDF) as a hydrophilic component. This allows control of the pore sizes in membranes. PVP is washed out at the end of manufacturing process by water to generate micro or nano pores for filtration, whilst some can remain in the membrane structure.

In new development “flat sheet”, Klucel™ hydroxypropylcellulose is used as pore former with PES which shows high efficiency in water flux. This development contributes to sustainability goals with naturally derived products.

Membrane production is often based on two different technologies: Thermally induced phase separation and solvent induced phase separation. Both processes lead to the formation of solvent poor and solvent rich phases. After removing solvent rich phase, pores are formed, which give the membrane its unique features.

M-pyrol (N-methyl pyrrolidone) is a polar aprotic solvent popularly used during membrane manufacturing processes. Solvent choice is a critical factor where it effects solvent evaporation time, temperature of casting gel, coagulation bath together with additive concentration would alter porosity and pore size distribution.

ceramic filter membranes

Purification of liquids through nano-, micro- or ultra-filtration is requiring ceramics with a well-defined porosity. Those ceramics, in tubular or sheet form, are often manufactured using extrusion processes. Good plastification for an optimal extrusion is key and so is shape retention. Ashland’s product portfolio offers various products as extrusion binders, which need to be chosen well for an optimal result. Depending on the used chemistries, the pore size can also be impacted.products

Membrane products are listed below, use the filters to find the products that meet your specific needs.

-

tobacco applications

who binds together to seal the deal? we do.

read more >Ashlands naturally derived cellulose ether products can be used in many production steps in the tobacco industry. From stabilizing tobacco dust slurries resulting in reconstituted tobacco sheets, over adhesives to glue tobacco leaves to finally sealing the mouth tip of a cigar.

culminal™ & benecel™ methylcellulose derivatives, natrosol™ hydroxyethylcellulose andaqualon and aqualon™ & blanose™ sodium carboxymethylcellulose are outstanding when used as a binder to achieve a homogenous slurry. During drying the presence of the binders minimizes cracks and shrinkage of the sheets. They also provide high tenacity (tearing strength), sheet elasticity and uniform appearance. In addition, these products can also be used as a glue to adhere tobacco products.

products

Products for the tobacco applications are listed below, use the filters to find the products that meet your specific needs.